Engineering

- Remote Visual Inspection (Videoscopy)

- Non-destructive essays

- Condition Monitoring

- Specialized Technical Support

With this study, it is possible to carry out a remote visual inspection of the equipment and its components without disassembling it through a videoscope. In this way, the condition of a piece of equipment is determined to establish future repair scopes, or even if a piece of equipment can continue operating or must be intervened immediately, this technique being a fundamental piece in ensuring predictive maintenance programs.

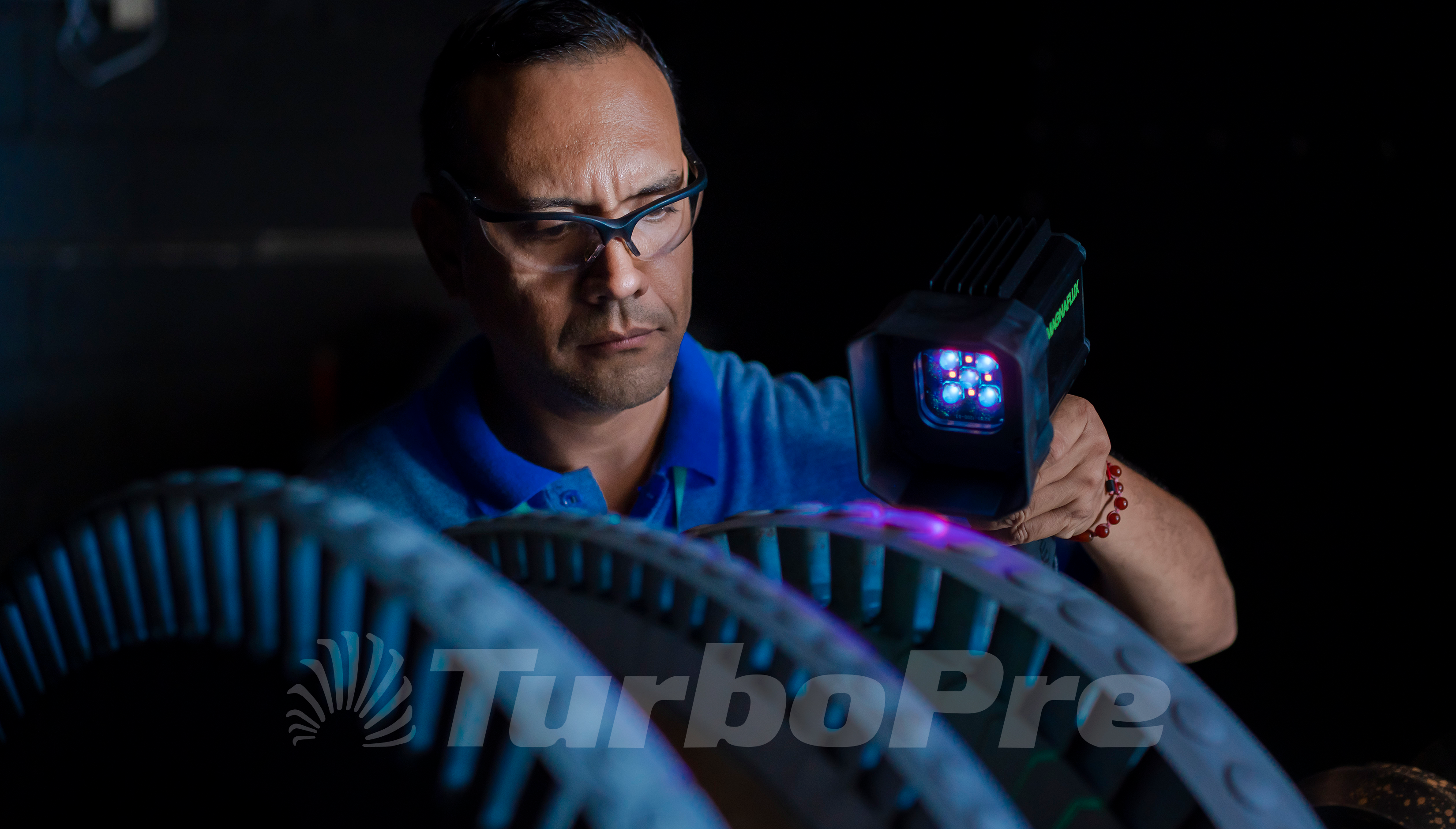

Non-destructive testing is an important part of production processes because they are applied to equipment and its components, in order to determine their physical condition. They allow cracks, corrosive attacks or internal fractures to be detected in each component of the equipment.

Thanks to our high-tech devices and highly qualified staff, we can provide exemplary service.

- Visual inspection

- Penetrating dyes

- Magnetic particles

- Phased Array

- Eddy Currents

- Ultrasound

The Condition Monitoring team, through first-level multichannel data collectors, analyzes the dynamic condition of all rotating equipment in order to provide evidence that allows timely corrections to be made to the equipment. Likewise, this service includes the analysis of rotor imbalance and correction through weight adjustments in the balancing planes of the component of any weight or generation capacity.

Within the team of consulting specialist engineers there are disciplines in the areas of gas and steam turbines, electric generators and compressors at the level of assemblies and repair procedures. Likewise, we have specialists in the control and operation systems of rotating equipment with extensive experience in commercial technologies at an international level.